Review of Business Operations

Overview of the Macroeconomic Environment

It was a year of nuanced economic recovery, globally as well as in Sri Lanka. Domestic consumption and investment were modest, however, and demand for credit was low. There was a visible recovery from the economic cooling that resulted from tighter credit controls imposed by the Central Bank of Sri Lanka in 2012, but many companies still reported declining profits or outright losses. Certain sectors of the economy, notably state-owned enterprises, hotels and tourism, industry and agriculture, did sufficiently well to ensure continued growth in the economy as a whole. In fact, according to the Central Bank, Sri Lanka’s GDP grew by 7.25% in 2013. Growth was supported by a more relaxed interest-rate regime, as well as by tax and other incentives granted to selected sectors.

In spite of the decline in interest rates, inflation moderated after peaking in the early months of the year, in part because of low consumption demand; this was reflected in a fall in the core inflation level to 2.1%, a record low, in December 2013. Headline inflation in March 2014, the latest figure available at the time of writing, was 4.2%.

Despite this, increases in the cost of electricity and fuels, which continued throughout 2012 and 2013, negatively impacted production costs. The cost of raw materials, however, diminished in many industrial sectors. This was due to a decline in global commodity prices.

Looking forward, moderate interest rates, subdued inflation and worldwide economic recovery improved prospects for the Sri Lankan economy in 2014, though it is still recovering from the effects of fiscal and monetary tightening in 2012. A number of large projects and new policies such as the Commercial Hub Act have enhanced the country’s investment potential and should help renew investor confidence and spur economic activity. Drought, a very real possibility in this El Niño year, may have a detrimental impact on the agricultural sector and hydropower generation, and hence on Sri Lanka’s current-account balance, fiscal position and inflation.

The outlook in the world economy is positive, led by recovery in the United States. However, economic uncertainty still prevails across the globe. Volatility is expected in emerging markets, particularly those with fiscal and external imbalances. Commodity prices are expected to remain relatively moderate.

Overview of the Construction Industry

The Institute of Construction Training & Development (ICTAD) and the National Construction Association of Sri Lanka (NCASL) are the apex bodies and accredited representatives of the Sri Lankan construction industry. Many state-owned entities and private construction companies are registered with ICTAD. Unregistered informal contractors and international contractors also carry out construction work.

Many large private-sector firms compete with Access Engineering in the Sri Lankan construction sector. Among them are International Construction Consortium (Private) Limited, Mäga Engineering (Private) Limited, Sierra Construction Limited and Sanken Construction (Private) Limited. The State is also a major player in the industry through the State Engineering Corporation, the Central Engineering Consultancy Bureau and the State Development & Construction Corporation.

Construction sector GDP stood at Rs. 247 Bn in 2012. The sector, which grew by 21.6% in 2012 (against overall GDP growth of 6.4%), experienced a continuing boom, whilst the provisional figures released for 2013 showcase a growth of about 15%. About half the total investment in the sector is in building construction; private-sector participation remains significant, particularly in building, water supply and drainage. The state sector was a key customer of the industry, particularly with respect to roads: a total of 594km of expressways and highways are being constructed under the National Road Master Plan. The cost of this programme, estimated at Rs. 238.3 Bn, will be spread over a period of ten years.

To pursue its policy of infrastructure development, the Government has taken steps to encourage private construction projects and eliminate bureaucratic, fiscal and other obstacles to foreign investment. It is also actively engaged in infrastructure projects on its own account, collaborating with large construction firms from China and India.

The construction industry did not benefit greatly from the global correction in commodity prices; raw-materials costs are rising. So are labour costs, as the migration of skilled labour to the Middle East and elsewhere has created a shortage.

Large-scale construction projects tend to be funded by loans. The recent reduction in policy rates by the Central Bank is expected to improve credit access due to a consequent reduction in the prime lending rate.

GDP Growth, Construction Sector vs. Total GDP

| 2013

Provisional |

2012

Revised |

Growth (%) |

||

| GDP at Current Prices (Rs. Mn) | 8,673,870 | 7,578,554 | 14.45 | |

| Construction Sector at Current Prices (Rs. Mn) | 894,683 | 712,272 | 25.61 | |

| GDP at Constant (2002) Prices (Rs. Mn) | Real Terms | 3,266,099 | 3,045,288 | 7.25 |

| Construction Sector at Constant (2002) Prices (Rs. Mn) | 282,742 | 247,091 | 14.43 |

Sri Lanka Construction Industry: Four-Year Analysis

| 2013 | 2012 | 2011 | 2010 | |

| Construction Sector (2002 Constant Prices, Rs. Mn) | 282,742 | 247,091 | 203,204 | 177,912 |

| GDP (2002 Constant Prices, Rs. Mn) | 3,266,099 | 3,045,288 | 2,863,715 | 2,645,542 |

| Contribution of the Construction Sector to GDP (%) | 8.66 | 8.11 | 7.10 | 6.72 |

| Growth in Contribution (%) | 6.69 | 14.35 | 5.51 | – |

| Employment in the Construction Industry | 588,000 | 616,000 | 590,000 | 550,000 |

| Total Labour Force | 8,418,000 | 8,118,000 | 8,197,000 | 7,894,000 |

| Contribution of Construction Sector (%) | 6.99 | 7.59 | 7.2 | 6.97 |

| Growth in Contribution (%) | -7.95 | 5.42 | 3.31 | – |

The Industry in Asia

Moving beyond the shores of Sri Lanka, we see the global construction sector at last beginning to recover from several years of slump, stimulated by economic recovery and increasing urbanization. In Asia, where economic fundamentals in most countries are robust and economic growth continues (though at lower rates than in the recent past), construction remains a significant and growing sector; in fact, Asia is today the largest regional construction market in the world, accounting for about 40% of global spending in the sector. In the near term, construction spending in Asia is likely to be concentrated on infrastructure, just as it is in Sri Lanka; in the longer term, there is likely to be a shift to residential building construction.

Going forward, private finance, including public-private partnerships, will play a key role in funding construction in Asia. As Access Engineering moves into overseas markets, we shall seek out and engage in more partnerships of this kind.

Business Operations: Engineering Projects

Roads & Highways

Rehabilitation and Improvements to A1 Highway between Kadawatha and Nittambuwa

|

Location : Gampaha District Client : Road Development Authority (RDA) Status : Ongoing Date of Commencement : September 2013 Projected Date of Completion : March 2015 Role : Main Contractor |

The section of the Colombo-Kandy road from Kadawatha to Nittambuwa has a total length of 23km. Access Engineering is transforming the existing two-lane road into a dual carriageway and providing adequate shoulder. The work involves extensive land acquisition and utility shifting, road widening and improvements to existing cross-drainage structures, town improvements with elevated footways, centre medians and islands, rehabilitation and improvement of road pavement and improvements to the existing drainage system.

Rehabilitation and Improvements to A32 highway between Navatkuli and Karaitivu

|

Location : Mannar District Client : RDA Status : Completed Date of Commencement : January 2012 Date of Completion : April 2014 Main Contractor : China Harbour Engineering Co. Subcontractor : Access Engineering |

Thirty years of war had left the A32, the primary link between Jaffna and Mannar, in ruins. This road is the only practicable means of access to war-damaged areas such as Vidatthaltivu, Mundampiddi, Vellankulam and Devil’s Point, and its condition imposed considerable hardship on recently resettled residents.

With Chinese Government funding, the GOSL initiated rehabilitation and improvements to a 67km length of the road. The principal contractor subcontracted the work to Access Engineering, which completed the works on 30th April this year.

Rehabilitation and Improvements to Jaffna-Kankesanthurai Road (AB16), Puttur-Meesalai Road (AB32) and Jaffna-Palali Road (AB18)

|

Location : Jaffna District Client : RDA Status : Completed Date of Commencement : February 2011 Date of Completion : November 2013 Main Contractor : China Railway No. 5 Subcontractor : Access Engineering |

The roads rehabilitated provide access to Palali domestic airport, Kankesanthurai seaport, the Chunnakam power station, and the communities of Inuvil, Kokuvil, Tellippalai, Keerimalai, Thirunelveli and Urumpirai. Puttur-Meesalai is a ring road, bypassing Jaffna town and connecting to the Palali and Kankesanthurai roads.

Under this rehabilitation programme, the existing 4.1m carriageways were widened to 8.2m and asphalted, with two lanes and a 1.0m cycle lane on either side. The completed roadways offer significant benefits to the 550,000 people who live in the Jaffna Peninsula.

Rehabilitation and Improvements to Mannar-Puttalam Road (B403)

|

Location : Mannar District, Puttalam District Client : RDA Status : Ongoing Date of Commencement : August 2012 Projected Date of Completion : June 2014 Main Contractor : China Harbour Engineering Co. Subcontractor : Access Engineering |

Good roads connect Puttlam with the southwest of the island. With the recent improvements to the A32 and the completion of the Sangupiddy bridge, good access to Mannar from Jaffna has been established. The improvement of the B403 will join Puttalam with Mannar and establish a continuous chain of good roads linking Colombo to Jaffna along the west coast for the first time in history.

The scope of work includes rehabilitation and improvements to the two-lane Mannar-Maricchikade-Puttalam road (B403), benefiting those travelling along west coast to the North, boosting the local economy and improving the quality of life of residents in adjacent areas.

Rehabilitation and Improvements to Ibbagamuwa-Kubukgate-Madagalle Road [B159]

|

Location : Kurunegala District Client : RDA Status : Completed Date of Commencement : March 2012 Date of Completion : March 2014 Role : Main Contractor |

Scope of work included the design and execution of improvements, widening the carriageway to 8m, resurfacing the road with asphalt concrete for a distance of 34.7km and providing drains on either side of the carriageway.

Rehabilitation and Improvements to Galagedara-Rambukkana Road [B122]

|

Location : Kandy District, Kegalle District Client : RDA Status : Ongoing Date of Commencement : June 2012 Projected Date of Completion : June 2014 Main Contractor : Xi’an Dagang Road Machinery Co. Limited Subcontractor : Access Engineering |

The object of this project was to improve the existing Galagedara-Rambukkana road and to cater increased traffic capacity. The existing road, 18.5km of length, is relatively narrow and contains many sharp, potentially dangerous bends and uncomfortable gradients. The improved road will reduce travel time and congestion and ensure safe and comfortable journeys.

Rehabilitation and Improvements to the Bangadeniya-Andigama-Anamaduwa Road [B045]

|

Location : Puttalam District Client : RDA Status : Ongoing Date of Commencement : November 2012 Projected Date of Completion : November 2014 Role : Main Contractor |

This section of road, situated in the North-Western Province and serving mainly as a route for the transportation of agricultural produce from the interior of the district to the coast, was in very poor condition. The current project, financed by Bank of Ceylon, includes the construction of four bridges, widening of the existing carriageway, asphalt surfacing and the construction of drains along either sides of the road.

Widening and Improvements to Jaffna-Ponnali-Point Pedro Road [AB021]

|

Location : Jaffna District Client : RDA Status : Completed Date of Commencement : September 2013 Date of Completion : March 2014 Role : Main Contractor |

The project called for widening the existing 1.5km long road from 5m to 19.2m, replacing the existing tarmac surface with a 14m carriageway together with 2m-wide paved footpaths on either side and a paved 1.2m centre median, and the erection of a total of 41 double-arm lamp posts. In addition, a 2km section of the B277 road was improved and widened to 5m.

Bridges and Flyovers

Polduwa Bridge

|

Location : Battaramulla, Sri Jayawardenapura, Kotte Client : RDA Status : Ongoing Date of Commencement : May 2013 Projected Date of Completion : November 2014 Role : Joint-venture partner with Mabey Bridge, UK |

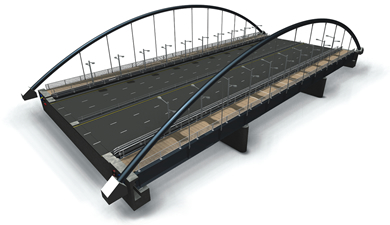

The completed bridge, presently under construction is a composite-steel girder bridge with a span of 71m and a six-lane deck to support a high volume of traffic. The project also improves flood control measures in the area and adds to the current beautification initiatives along the banks of the Diyawanna. The scope of work includes engineering design, construction of the substructure (including pier, abutments, arch anchors, temporary works and scour protection), erection and launch of the superstructure, deck concreting asphalting and constructions of approach roads.

Bridges in the Eastern and the North-Central Provinces

|

Location : North-Central & Eastern Provinces Client : Provincial RDA (Eastern) Status : Completed Date of Commencement : August 2011 Date of Completion : July 2013 Role : Main Contractor |

Post-war infrastructure development in the North and the East of the country has involved the construction, reconstruction or rehabilitation of a number of bridges and culverts along roads in the area. Under the Eastern and the North Central Provincial Bridge Project, Access Engineering was entrusted with the design and construction of five bridges and six multicell culverts.

Consultants for the project were Cardno Emerging Markets (Australia) Limited in association with Engineering Consultants Limited and MG Consultants Limited.

Flyover to Replace Railway Crossing at Veyangoda

|

Location : Veyangoda, Gampaha District Client : RDA Status : Completed Date of Commencement : October 2012 Date of Completion : October 2013 Main Contractor : CENTUNION Española de Coordinación Subcontractor : Access Engineering |

The Veyangoda-Ruwanwella road provides access to Katunayake Airport from the Central and Sabaragamuwa Provinces. It also links the three largest free-trade zones in Sri Lanka, provides access routes to major hospitals and connects several populous towns, including Gampaha, Negombo and Nittambuwa.

The flyover consists of a steel superstructure supported by a pile foundation. The 9.4m-wide carriageway consists of two lanes and has a length of 255m. The project also includes the construction of an access road of length 345m. Completed flyover will help relieve traffic congestion in Veyangoda due to level-crossing gate closures.

Water and Wastewater

Labugama and Kalatuwawa Water Treatment Plants

|

Location : Central and Sabaragamuwa Provinces Client : National Water Supply and Drainage Board (NWSDB) Status : Ongoing Date of Commencement : September 2013 Projected Date of Completion : June 2016 Main Contractor : Fovárosi Vízmevek, Hungary Subcontractor : Access Engineering |

The object of this project is to increase the production capacities of both plants to their original capacities of 60,000m3/day at Labugama and 90,000m3/day at Kalatuwawa. Currently, their respective capacities have diminished to 40,000m3/day and 70,000m3/day. Work undertaken by Access Engineering includes the renovation and replacement of existing filters and clarifiers, intake well improvements, modifications to the aerators and other process structures, the design, supply and installation of all mechanical and electrical equipment, reconstruction and renovation of the existing buildings, internal roads and site works.

Ductile-Iron Transmission Main from Kantale to Ganthalawa

|

Location : Trincomalee District Client : NWSDB Status : Completed Date of Commencement : March 2012 Date of Completion : March 2013 Role : Main Contractor |

Following the improvement and widening of the A6 highway between Kantale and Ganthalawa, there was an urgent need to shift the existing water line away from the newly improved carriageway to avoid damage to the road during pipe repairs and maintenance works. The scope of work on this Rs. 234.2 Mn project included the relocation of distribution mains from Kantale to Ganthalawa (approximately 10km) and the supply and laying of a 400mm ductile-iron transmission main from Ganthalawa to Thambalagamuwa, a distance of approximately 6km. Also included were the supply, delivery and laying of fittings, valves and accessories.

Kalu Ganga Water Supply Project: Kandana Water Treatment Plant Extension

|

Location : Kandana, Horana Client : NWSDB Status : Ongoing Date of Commencement : March 2013 Projected Date of Completion : March 2015 Main Contractor : Salcon Engineering Bhd Subcontractor : Access Engineering |

The aim of this project is to meet the increasing demand for drinking water in Southern Greater Colombo. A total of 250,000 people living in Kesbewa, Piliyandala, Jamburaliya, Kumbuke and surrounding areas will be benefited by this expansion.

The scope of work includes the construction of access roads to the water treatment plant together with bridges and drainage, sedimentation and flocculation tanks and construction of an engineering office, as well as the installation of a filter unit and all other civil, mechanical, electrical and Instrumentational Control Monitoring System (ICM) works.

Kadurugaldola Mini Hydro Power Project

|

Location : Pahalagama, Sabaragamuwa Province Client : Eco-Friendly Power Developers (Private) Limited Status : Completed Date of Commencement : February 2012 Date of Completion : August 2013 Role : Main Contractor |

The scope of this project comprised the construction of a concrete weir across the Kadurugaldola watercourse, a high-head penstock pipeline 970m in length with a head difference of 126m and a powerhouse to accommodate two turbines and two 800kw generators for a total power generating capacity of 1.6MW, together with a 500m transmission line, anchor blocks and piers, and chemical anchoring. The project was situated in difficult terrain and demanded laborious, large-scale manual excavations. In addition to conventional blasting, rock splitter and chemical-blasting techniques were used to remove large rock boulders.

Gated Salinity Barrier across Walawe River at Ambalantota

|

Location : Ambalantota, Hambantota District Client : NWSDB Status : Completed Date of Commencement : January 2010 Date of Completion : March 2013 Role : Joint-venture partner with China Geo |

Water resources from the Walawe River are used for irrigation, power generation and drinking water in the Hambantota District. However, during the dry season, raw water abstraction from Walawe River intake is highly restricted due to low flow conditions and the intrusion of salinity. To deal with this problem, a gated salinity barrier was installed to prevent upstream saltwater intrusion and maintain water levels

at >1m above mean sea level during dry spells. The project also enhances raw-water extraction by 28,000m3/day, meeting projected demand in the Hambantota District until 2025.

The barrier consists of an 18.7m-wide reinforced-concrete base across the river, six reinforced-concrete piers and two abutment walls. Five vertical wheel gates with hoist mechanisms have been installed, together with one sluice gate and a gantry crane. The scope also covered the installation of a riverbed protection system, construction of upstream and downstream embankment protection walls, and landscaping.

Buildings

UDA Housing Units, Henamulla

|

Location : Henamulla, Colombo 15 Client : UDA Status : Ongoing Date of Commencement : October 2011 Projected Date of Completion : August 2014 Role : Main Contractor |

Access Engineering has been entrusted with the design and construction of five 12 storey apartment blocks, comprising 1,137 housing units in total. All engineering services, including structural designs, piling, design and installation of mechanical, electrical and plumbing works, landscaping, etc., are being provided using in-house expertise and capabilities. Included in the project scope is rehabilitation of the access road to the development. The building design makes optimal use of natural light and ventilation to reduce power consumption by residents.

A significant feature of this project is the use of a state-of-the-art formwork system, which has helped reduce construction time and improve quality and efficiency.

Auditorium Building, Methodist College, Hakmana

|

Location : Hakmana, Southern Province Client : Methodist College, Hakmana Status : Completed Date of Commencement : March 2012 Date of Completion : June 2013 Role : Main Contractor |

This project was initiated by Access Engineering as a corporate social responsibility initiative. It included the design and construction of an 8,500sq. ft. auditorium building with a raked, polished cement floor and comfortable seating for 650 people, together with two dressing rooms, two toilets, modern theatre lighting and sound reinforcement, a well-designed ventilation system and a modern control room. The auditorium features an elevated 1,250sq. ft. timber stage with stage curtain. The area surrounding the building was also landscaped by Access Engineering.

Telecommunications Infrastructure

Dialog Aerial Optical Fibre Network Project, Phase III

|

Location : Island-wide Client : Dialog Broadband Networks (Private) Limited Status : Completed Date of Commencement : June 2013 Date of Completion : February 2014 Role : Main Contractor |

Access Engineering supplied services related to the deployment of the Dialog Broadband optical-fibre network, including surveying, supply of cables, installation, testing and commissioning. The work involved pre-installation surveying, supply and installation of ducts, the installation of manholes and hand holes, road reinstatement, installation of cables, splicing and testing. In all, a total of almost 210km of fibre was laid along the following routes: Kottawa to Avissawella, Ambepussa to Mawanella and Nuwara Eliya to Madulsima.

Colombo Metro Optical-Fibre Network Project

|

Location : Colombo District Client : Dialog Broadband Networks (Private) Limited Status : Completed Date of Commencement : January 2010 Date of Completion : October 2013 Role : Main Contractor |

The salient feature of this project was the use of Horizontal Direction Drilling (HDD) technology, a steerable, trenchless method of installing underground pipes and ducts with minimal impact on the surrounding environment. Cable jetting, in which air is forced into the duct under pressure to reduce distributed friction between duct and cable as the cable is simultaneously pushed into the duct at high speed, was another technology that featured in this project.

Dialog Metro and SPROUTS Connectivity Project

|

Location : Colombo and Island-wide Client : Dialog Broadband Networks (Private) Limited Status : Ongoing Date of Commencement : January 2014 Projected Date of Completion : August 2014 Role : Main Contractor |

The project involves the supply of services related to the Deployment of Dialog Broadband’s optical fibre network including pre-installation survey, supply of ducts, network development (including indoor works), installation of ducts, manholes and hand holes, road reinstatement, installation of cables, splicing and testing, and commissioning the project. In all, a total of 26,713m will be laid in Colombo with connectivity at 107 sites, plus a further 85,527m island-wide with connectivity at 90 sites.

Sri Lanka Telecom (SLT) New Subscriber Connection Project

|

Location : Galle and Hambantota Client : SLT Status : Ongoing Date of Commencement : January 2013 Projected Date of Completion : January 2015 Role : Main Contractor |

Under this project, Access Engineering is to execute the provision of new telephone connections in Galle and Hambantota areas.

Dialog/Hutch Telecom Tower Project

|

Location : Northern Province Client : Dialog/Hutch Status : Completed Date of Commencement : May 2012 Date of Completion : August 2013 Main Contractor : Huawei Technologies, China Subcontractor : Access Engineering |

Under this project, 11 telecommunications towers were erected across the Northern Province to improve transmission facilities in rural areas.

Harbours and Marine Work

Unity Container Terminal

|

Location : New North Pier, Port of Colombo Client : Sri Lanka Ports Authority Status : Completed Date of Commencement : December 2011 Date of Completion : February 2013 Role : Main Contractor |

Access Engineering’s input to this development included dredging, construction of a rubble-mounted embankment along the west and north revetments to protect quay settlement, rectification of the settlement with anchor rods and tie rods, construction of an underwater mass concrete curtain wall 9-11m in height along the inside face of the revetment to prevent further quay settlement, and restoration of the yard area.

The Company was also entrusted with the provision of essential amenities, including electricity cables to the yard light towers and rehabilitation of the south gantry crane rail foundation.

Facility Openings and Closures - Projects

Project offices were opened at the following locations, where new projects commenced during the year: Ibbagamuwa, Kadawatha, etc. A project office was also opened in Lae, Papua New Guinea, in connection with our project there. PMD (Project Management Divisions) 1 & PMD 2, which were located at Boralesgamuwa, were shifted to our head office at Union Place in December 2013.

Business Operations: Engineering Services

In the field of engineering solutions, Access Engineering is focused on providing value added ‘A-Z engineering solutions’ that cover the full gamut of a client’s needs at every stage of the project cycle. Backward integration forms the backbone of this concept. Innovation, too, is an essential part of it; while we certainly don’t believe in reinventing the wheel, we understand that every problem is unique and often demands a unique solution. We work constantly to improve delivery speeds, produce better construction material and optimize the use of resources.

In addition to dealing directly with end customers, we also provide engineering services to other engineering organizations, some of whom are in fact leading players in the sector.

Engineering Design

The Engineering Design Division provides Access Engineering with a competitive edge in turnkey and design-and-build contracts. Collectively, its team of engineering design professionals fields expertise and experience relevant to most civil engineering disciplines. In particular, the team is skilled in design of bridges, flyovers and viaducts, road and highway design, building design (including high-rise buildings), dams and other water-retaining structures, foundations and ground improvements. The division is equipped with state-of-the-art design and analysis software backed by top-end hardware.

Projects, Design Engineering - 2013/14

| Name | Description | Type | Inception | Client | |||||||||

| Anamaduwa-Bangadeniya Road Project | Geometric and pavement design | Road | 2013 | RDA | |||||||||

| Galagedara-Rambukkana Road Project | Culvert design | Road | 2013 | RDA | |||||||||

| Ibbagamuwa-Madagalla Road Project | Design check | Road | 2013 | RDA | |||||||||

| Polduwa Bridge, Battaramulla | Design of civil works for steel bridge across Diyawanna Oya | Bridge | 2013 | RDA | |||||||||

| Rehabilitation of Labugama-Kalatuwawa water treatment plant | Structural design of plant, buildings and other water supply systems | Water supply | 2013 | NWSDB | |||||||||

| Access Tower II | Design of 28-storey office building | Building | 2013 | AEL | |||||||||

| Sri Lanka Regional Bridge Project | Design of civil works for 20 steel bridges | Bridges | 2013 | RDA | |||||||||

| UDA Housing Project, Phase II | Design of 15-storey buildings (four blocks) | Building | 2014 | UDA |

Piling

Over the years, Access Engineering has become one of the leading piling contractors in Sri Lanka, renowned for its reliability and expertise as well as for the quality of its mechanical resources. These include six Bauer BG24 and BG25 rotary drilling rigs and associated equipment and a fleet of cranes, excavators, loaders and dump trucks. Other equipment includes de-sanders for the recycling of bentonite - an eco-friendly technology that also helps produce a higher quality pile - and four percussion pile rigs. The piling unit undertakes static load testing (maintained load testing) and other tests on piles.

Piling Unit - 2013/14

| Project | Volume of Concrete Utilized (m3) |

|

| Greater Colombo Urban Transport Development Project, Colombo Outer Circular Highway (Northern Section 1) | 29,792 | |

| Urban Regeneration Project, Colombage Avenue housing development (1,776 units) | 817 | |

| Access Tower II, Access Realties, Union Place, Colombo 2 | 1,586 | |

| Total | 32,195 |

By far the largest and most demanding of these projects is the Colombo Outer Circular Highway, where AEL was a subcontractor to Taisei Corporation. In 17 months, a total of 1,700 cast-in-situ bored piles of diameter 1.5m were installed to an average depth of 11.8m to support the superstructures of a number of bridges and viaducts, the total length of which was 6.5km. Cutting-edge technology, appropriate booting tools and a range of sophisticated machinery had to be used to suit the diverse geology and sensitive natural environment in which the work was carried out.

Geotechnical Laboratory Services

Within few years of its establishment, this unit has become a valuable asset to the Company, providing essential scientific services cost effectively on demand. These services include the testing of raw and processed materials and products for engineering use, aggregate testing, geotechnical investigations and soil testing, surveying, levelling and traffic surveys, utility surveys, quality assurance services for infrastructure projects, pile load testing and concrete mix design. All procedures are conducted to ISO 9001:2008, ISO 14001:2004 or ISO 17025 standards, as appropriate.

This is the only construction and engineering laboratory licenced by the Sri Lanka Accreditation Board to provide ISO 17025 standard services. Various operations undertaken by the unit in 2013/14 are displayed below:

Geotechnical Laboratory Services - 2013/14

| Project/Client | Work Involved | |

| Dialog Aerial Optical Fibre Network Project | Concrete cube testing for pole casting | |

| SPROUTS | Concrete cube testing for hand hole and pole casting | |

| Internal: Mabima Batching Plant | Quality assurance testing | |

| Polduwa Bridge | Geotechnical investigation (phase I & II), source approval and PIT testing | |

| RLKWTPP | Source approval and concrete cube testing | |

| Henamulla Housing Project | Geotechnical investigation (Buildings 1 & 2), pavement investigation tests and QC tests | |

| PDNK (outsource batching plant) | Concrete cube testing | |

| Lanka Sugar Refinery Corporation | Geotechnical investigation and source approval tests | |

| Access Tower II Project | Geotechnical investigation | |

| Sri Lanka Regional Bridge Project | Geotechnical investigation | |

| Tudawe Brothers Limited | Concrete cube testing for Henamulla building project | |

| Urban Development Authority | Concrete cube testing for Kotahena building project | |

| Colombo Outer Circular Highway | Laboratory services, QC work and pile coring | |

| Veyangoda Flyover | Laboratory services, pavement investigation tests and source approval tests |

HDD and Cable Jetting

Horizontal Directional Drilling (HDD) is a state-of-the-art drilling technique used to install pipes/ducts underground without disturbing the structures, such as buildings, highways and watercourses, above the installation location.

Access Engineering was the first-ever construction company in Sri Lanka to use this technology, which it introduced in 2008. In order to avoid potential damage to underground utilities, our HDD systems utilize ground penetrating radar to identify obstacles and existing utilities prior to surface penetration.

Cable jetting is the process of installing fibre-optic cable in a duct by pushing the cable into the duct at high speed while simultaneously blowing air under pressure through the duct to reduce friction. This is a greatly superior alternative to manual installation, saving time and eliminating cable damage due to handling.

In the year under review, HDD operations to a total drilling distance of 32,665m were carried out at a per-hour efficiency rating of 13.61.

Dredging

Access Engineering is equipped with a Beaver 300 cutter-section dredger of 50m3/hr capacity and a maximum operating depth of 6m, featuring the ability to transport dredged materials up to 1km from the work-site. Yet again, AEL was the first ever Sri Lankan company to deploy this capability.

Employed at a project site in Kosgoda, the dredger was operational for a total of 428.9 hours in 2013/14, dredging a total of 14,931m3 at an average efficiency of 34.81m3/hr.

Asphalt Concrete

Given the scope of our operations, it is natural that many of our services should be focused on road and highway works. In order to stabilize operational sustainability and build synergies through investment integration, Access Engineering has established a number of asphalt mixing plants to support its own road and highway projects as well as to supply asphalt to external customers. These plants, currently operating at optimum capacity, ensure the timely supply of high quality asphalt products to keep our projects, and those of our customers, on schedule.

Asphalt Concrete Output - 2013/14

| Plant | Sales Quantity 2013/14 (mt) | Cumulative as at 31st March 2014 (mt) | Total Plant Capacity (mt/hr) | |

| Kotadeniyawa | 38,375 | 156,162 | 96 | |

| Jaffna | 41,069 | 94,366 | 120 | |

| Ibbagamuwa | 50,391 | 68,126 | 120 | |

| Vavuniya | 28,062 | 60,378 | 120 |

Quarry Operations and Aggregate Production

The current project portfolio of the Company has created a very high demand for asphalt, concrete and dense-grade aggregates, for which crushed aggregates are an essential raw material. To promote operational sustainability and backward integration, the Company has established several quarries and crusher plants at convenient locations across the country. Apart from meeting the Company’s own needs, the output of these facilities also supplies many external customers.

Quarries and Crusher Plants - 2013/14

| Plant | Sales Quantity 2013/14 (cubes)* | Cumulative as at 31st March 2014 (cubes)* | Plant Capacity (mt/hr) |

| Vavuniya Quarry | 55,705 | 133,592 | |

| Kotadeniyawa Quarry | 13,085 | 35,464 | |

| Total | 68,790 | 169,056 | |

| Kumbukgate Crusher Plant | 15,452 | 37,962 | 50 |

| Vavuniya Crusher Plant | 50,311 | 114,674 | 150 |

| Kotadeniyawa Crusher Plant | 14,985 | 56,713 | 80 |

| Total | 209,349 |

* 1cube = 100 cu.ft.

Supply of Readymix Concrete

Access Engineering provides readymix concrete to both internal and external customers through its concrete plants. Operational output of our plants in 2013/14 is shown below:

Readymix Concrete - 2013/14

| Batching Plant | Sales Quantity 2013/14 (m3) | Cumulative as at 31st March 2014 (m3) | Plant Capacity (m3) |

| Kandana (CBKN) | 3,890 | 12,115 | 25m3/hr |

| Mabima | 49,975 | 88,629 | 60m3/hr |

Mechanical Workshops and Steel Fabrication

The Company’s mechanical workshop services, maintains and repairs all its heavy machinery and equipment, as well as its heavy vehicle fleet. It also provides support services to construction projects being carried out by the Company.

An in-house fabrication unit customizes machinery and designs and manufactures various objects and devices required for different projects, including water tankers (‘bowsers’), fuel tanks, etc.

The tables below represent workshop output for the year under review:

Mechanical Workshop - 2013/14

| Job Description | Output |

| 34x tipper trucks (capacity 3 cube) | 858,464km (laden) |

| 11x backhoe loaders | 12,221hr |

| Transport fleet (1x prime mover with H/B & L/B trailers, 4x H/B open trucks, 8x boom crane trucks) | 359,697km (laden) |

| Other construction machinery | 18,927hr |

| Other vehicles | 916,688km |

| Maintenance services (vehicles and construction machinery) | 265 |

| Major overhauls, repairs and modifications (construction machinery and vehicles) | 13 |

| Running repairs (vehicles and construction machinery) | 747 |

Fabrication Workshop - 2013/14

| Job Description | Steel Used (mt) |

| Fabrication and installation of cross bridge and pipe brackets | 10.81 |

| Fabrication and installation of feeder hoppers w/additional work | 69.98 |

| Gypsum hopper rectification w/additional work | 0.68 |

| Fabrication of 10,000l water-bowser tank | 2.10 |

| Fabrication and supply of dogging device | 0.88 |

| Fabrication and supply of piling casing (1,010mmø x 6mmW x 4mL) | 0.62 |

| Fabrication and supply of 4 piling casings (1,010ø x 6mmW x 4mL) | 1.24 |

| Retaining-wall formwork | 2.10 |

| Fabrication and supply of pipe bracket | 6.23 |

| Fabrication of 10,000l and 15,000l water-bowser tanks | 5.20 |

| Fabrication of steel strusses for PMD 1 (without material) | – |

| Fabrication and supply of piling casing (810mmø x 6mmW x 6mL) (3 Nos.) and 610mmø x 6W x 6mL (6 Nos.) | 5.46 |

| Intake-pit fabrication work | 1.98 |

| Piling casing 1,500mmø x 12mmW x 6mL | 2.70 |

| Piling casing 800mmø x 6mmW x 3mL | 0.40 |

| Bentonite platform | 0.60 |

| Bentonite box | 0.70 |

| Concrete box 1.5 x 3 x 8m | 0.25 |

| Tremie rack | 1.70 |

| Supply of piling casing 610mmø x 6mmW x 6mL (8 Nos.) | 4.56 |

| Fabrication and supply of tremie funnel 1.5m3 | 0.75 |

| Fabrication and supply of impact chisel | 7.80 |

| Supply of piling casing 610mmø x 6mmW x 6mL | 0.60 |

| Fabrication and supply of tremie funnel 1.5m3 | 0.75 |

| Fabrication and supply of bentonite silo (2 Nos.) 1,500 x 600mm | 2.20 |

| Piling tool repair | – |

| Supply and installation of tool hut | 8.20 |

| 12mm plate supply | 0.31 |

| Fabrication and supply of piling casing 810mmø x 12mmW x 14.4mL | 3.68 |

| Fabrication and supply of piling casing 610mmø x 12mmW x 14.4mL | 2.86 |

| Modification of mud bucket | 0.84 |

| Fabricate and supply of piling casing 610MMø x 12mmW x 28.8mL | 5.72 |

| Fabrication and supply of piling casing 1,000mmø x 12mmW x 12mL | 3.68 |

| Fabrication and supply of piling casing (1,500mmø x 16mmW x 6mL | 7.80 |

| Total | 163.37 |

Facility Openings and Closures - Services

| Facility Openings | Facility Closures | Expansions |

| Ibbagamuwa Asphalt Plant | Thalawa Asphalt Plant | None |

| Vavuniya Asphalt Plant | Kantale Asphalt Plant | |

| Kumbukgete Crusher Plant | Kandana Concrete Batching Plant | |

| Ibbagamuwa Crusher Plant | ||

| Kantale Crusher Plant |